DFA – Digital Fingerprint

DFA – Digital Fingerprint

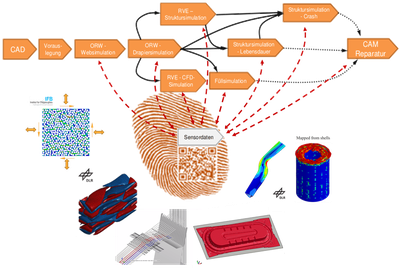

The subsequent project of the Digital Prototype DigitPro (see https://www.dynamore.de/en/services/projects/examples/arena2036) is called Digital Fingerprint (DFA) and aims for the “intelligent data collection, processing, and transfer along the entire value chain – from the idea, design, production, and in-service to the end-of-life - for the intelligent component and the versatile autonomous factory of the future!” (https://www.arena2036.de/en/digital-fingerprint). Therefore, the already existing consortium has been enriched with further partners taking care of data management and sensor integration into the manufactured components. Together with virtually tested and stochastically distributed material parameter on a micro-, meso-, and macroscopic level, sensor data shall enrich the simulation data in order to allow for in-service failure detection, miss-use evaluation and component evaluation even during the production phase.

The final goal is to show that for each component, all data being measured during life-time and production can be stored and used for simulations in the event of unexpected behavior in order to estimate remaining durability and strength for each individual digital twin based on its own history. Therefore, the already closed simulation process chain from DigitPro will be extended with sensor data measured during the components production- and in-service life-time.